About Air Bearing

What is the air bearing?

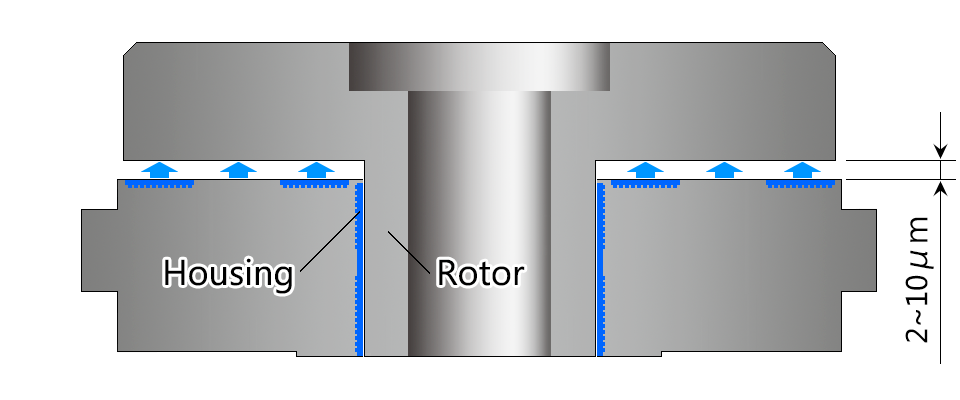

From the housing, compressed air of 0.3Mpa ~0.7Mpa gushed through the diaphragm to the sliding surface. That makes static pressure generated and the rotor float. Air bearing is the bearing which performs rotary motion without contact by making the rotor float with generated static pressure.

Application

Air bearing is incorporated in equipments which require special precision and contributes to the performance enhancement of the industrial instruments.

1. Machine tool

High-precision upright lathe

Surface grinder

2. Measuring instrument

Scale meter measuring machine

Roundness measuring machine

Characteristic of Canon's product

1. High accuracy :Achieved No.1 accuracy of the industry in the radial and the axial directions.

In comparison with ball bearings, air bearings have extremely high rotation accuracy, equal or less than 0.05μm.

When you seek further accuracy, the most important thing is that the reproducibility is equal or less than 0.01μm, and at that time, its quality is kept semi-permanently.

To meet high performance demands, it is important to choose chronologically changeless materials and to fabricate them in the appropriate process.

2. High stiffness :By the diaphragm and our original method, the enough stiffness and the load capacity are secured even under normal factory air supply pressure (0.5Mpa).

3. Reliability :Burning trouble is dramatically resolved with self-lubricating sliding surface and finishing method of rotating parts.

We adopt the carbon system porous material in order to resolve burning and unrepairable troubles which are caused by air supply accident during the rotation.

The high durability also enables to enhance its reliability for use.

※Self-lubricating carbon system porous material … Friction and abrasion-resistant characteristic that the carbon system porous material originally has. Porous material means the material which has many pores (fine holes).

※Burning or unrepairable trouble caused by air supply accident … The state that the sliding surface and the rotating parts contact each other, get burned, and finally the graphite get damaged unrepairablly. That is caused by the interception of air due to the collision of the machine by wrong operation or due to blackout or others.

4. Economic efficiency :Little air consumption by the original sliding surface finishing method.

Little air consumption enable to use the economical compact-sized air compressor.

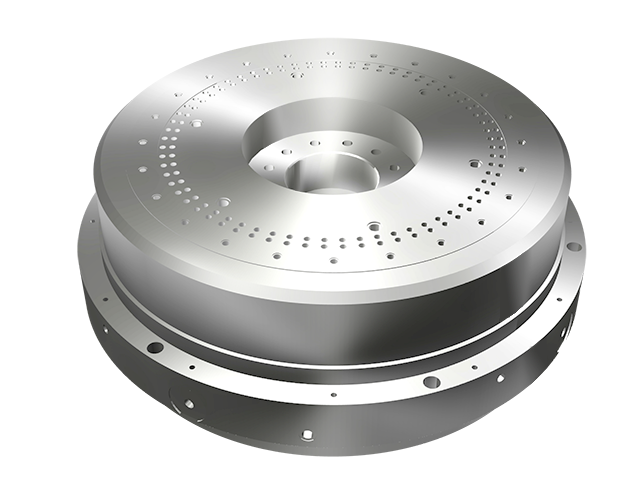

5. Variety :18 various types of lineup from 30R to 600R.

We provide various sizes of air bearings. As for 600R, we realized the space-saving structure that held overall height to extremely low by our original one side static pressure structure.

※One side static pressure structure … The structure which only upper plate controls the thrust direction.